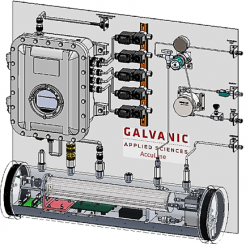

AccuLase-GPA™ TDL H2S, CO2, H2O Analyzer

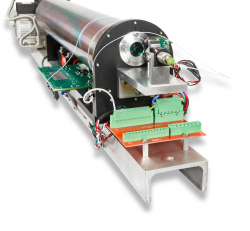

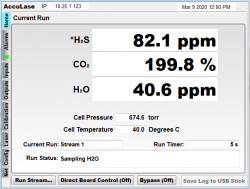

The only tunable diode laser (TDL) analyzer that measures H2S, CO2, and H2O using 1 Herriot Cell.

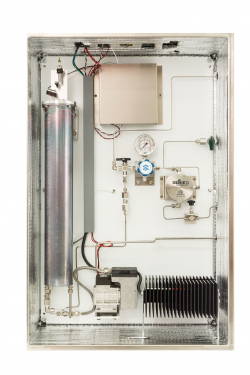

AccuLase-GPA™ was designed for specific natural gas and refinery applications. AccuLase is backed by 40 years of experience in the natural gas industry.

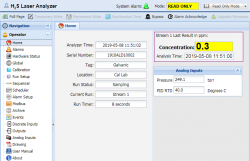

AccuLase-GPA™ uses a proprietary measurement cell that detects H2S down to 0.15 ppm, rivaling the capabilities of lead-acetate tape technology. AccuLase-GPA™ is specific to H2S without methane, CO2, or benzene interferences. Since AccuLase-GPA™ does not require a scrubber system, the response time is rapid. AccuLase-GPA™ can measure up to 4 streams.

Are you looking to avoid pipeline network “lock-out,” corrosion, or off-spec product? Do you need to automate custody transfer validation or better ensure contractual/regulatory compliance? Then AccuLase is the analyzer you need for operational certainty.