Brimstone™ Sulfur Recovery Analyzers

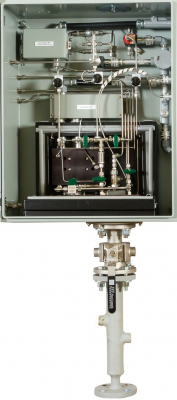

Direct coupled tail gas and pit gas analyzer for sulfur recovery units. Monitors H2S, SO2, COS and CS2 and calculates air demand.

Brimstone analyzers support tail gas, pit gas, and acid gas SRU applications. Galvanic is well known as the leader in process analyzers used to optimize sulfur-recovery units. We put 25 years of applications know-how and engineering prowess into the rugged, user-friendly design of the UV-spectrophotometer-based Brimstone analyzer line.

The Brimstone family includes a full line of analyzers designed to assure quality, efficiency, and compliance throughout the entire sulfur-recovery process: an acid gas analyzer to assess the inlet stream, a tail-gas analyzer to control air demand during the Claus process, a pit-gas analyzer to optimize and monitor the captured sulfur during the process, and a continuous emissions monitor to assure that stack gas complies with environmental regulations. Enhanced CCD UV spectroscopy delivers extremely fast, accurate results. Engineered for low-maintenance performance with no moving parts, Galvanic’s Brimstone analyzers free up operators to focus on other critical functions.

One-of- a-Kind Tail and Pit Gas Analyzer; with H2S, SO2, CS2 and COS monitoring capabilities

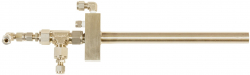

The Brimstone is a unique tail & pit gas analyzer that monitors H2S, SO2, CS2 and COS and is capable of direct coupling to the process. Direct coupling provides the Brimstone with the ability to control sulfur vapor removal more efficiently. Galvanic’s proprietary probe design eliminates plugging problems associated with heated transfer lines. In addition, the Brimstone uses Chemometrics to measure all four key components; H2S, SO2, CS2 and COS simultaneously. This is a superior method because it measures absorption at 256 points versus the standard single point analysis.

As the only tail & pit gas analyzer with these combined capabilities and features, the Brimstone is a truly exceptional and innovative product that provides unique process analysis in sulfur-recovery.