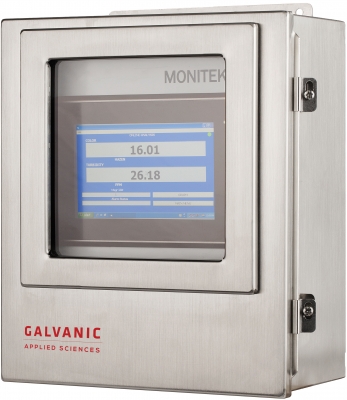

Monitek™ In-line Turbidity, TSS, Color

Turbidity, suspended solids and color analyzer for liquid samples.

Whether you’re brewing beer, optimizing critical pharmaceutical-manufacturing processes, or monitoring industrial wastewater for contamination, you need rugged, reliable, real-time results to optimize your processes and assure consistent quality and regulatory compliance. Galvanic delivers with its Monitek optical-technology-based turbidity, suspended solids, and color monitors, which delivers the highest performance-to-cost ratio of any in-line liquid process monitor on the market today.

The Utmost in Flexibility to Meet Your Toughest Analytical Challenges

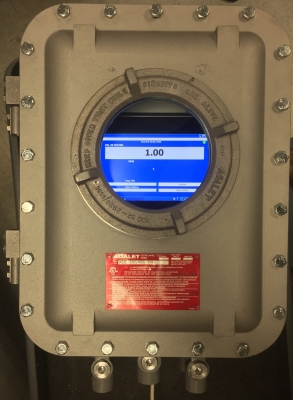

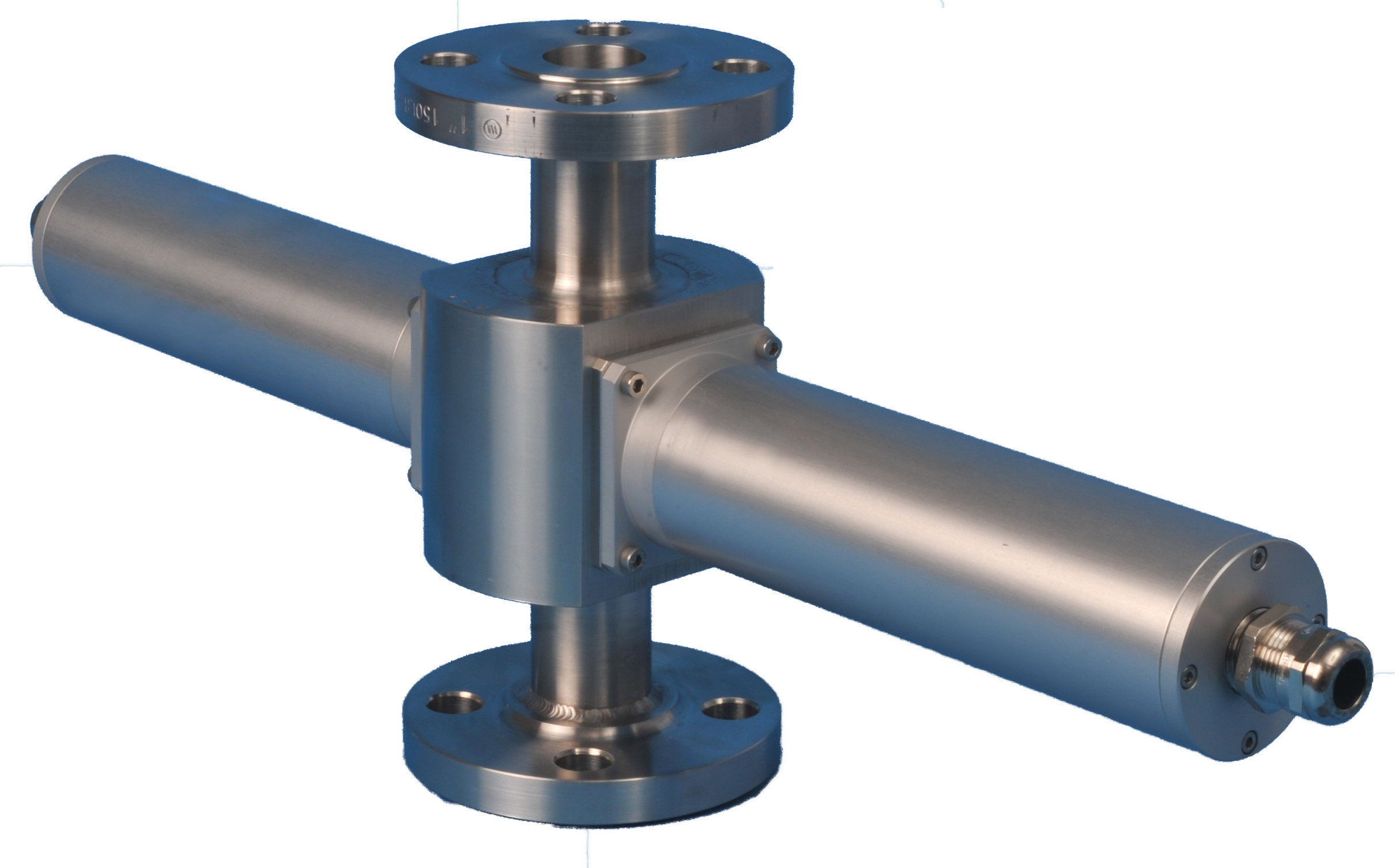

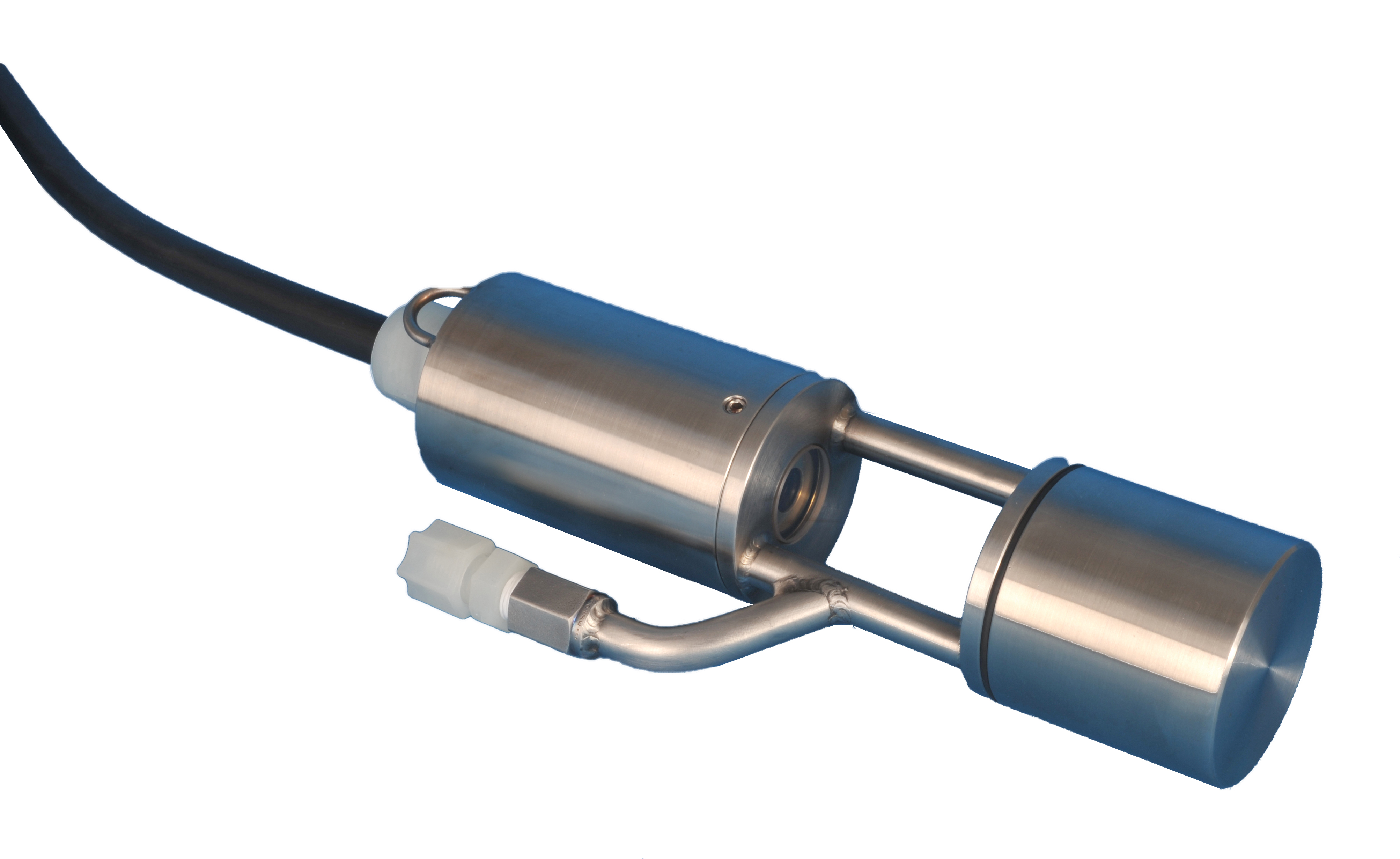

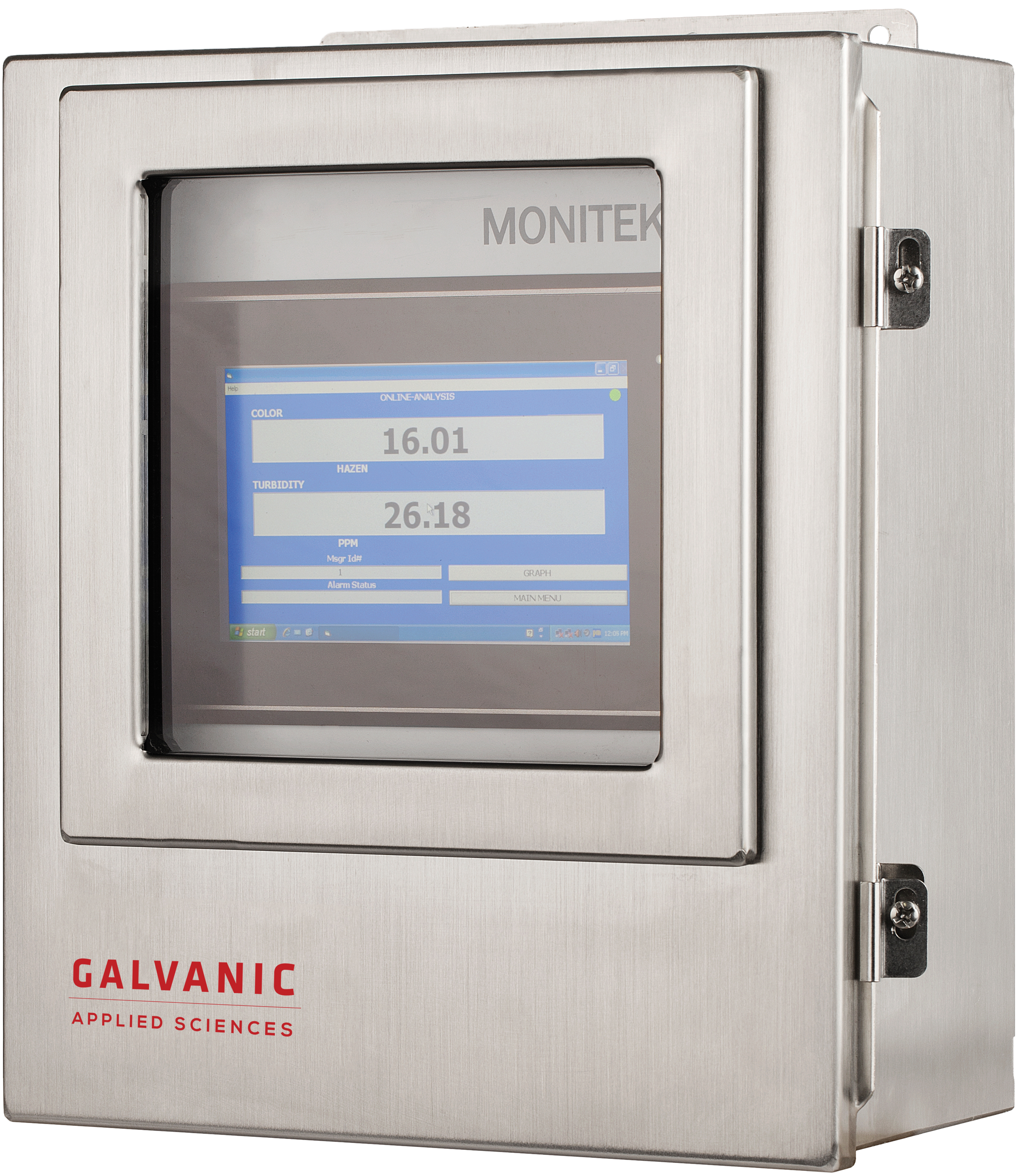

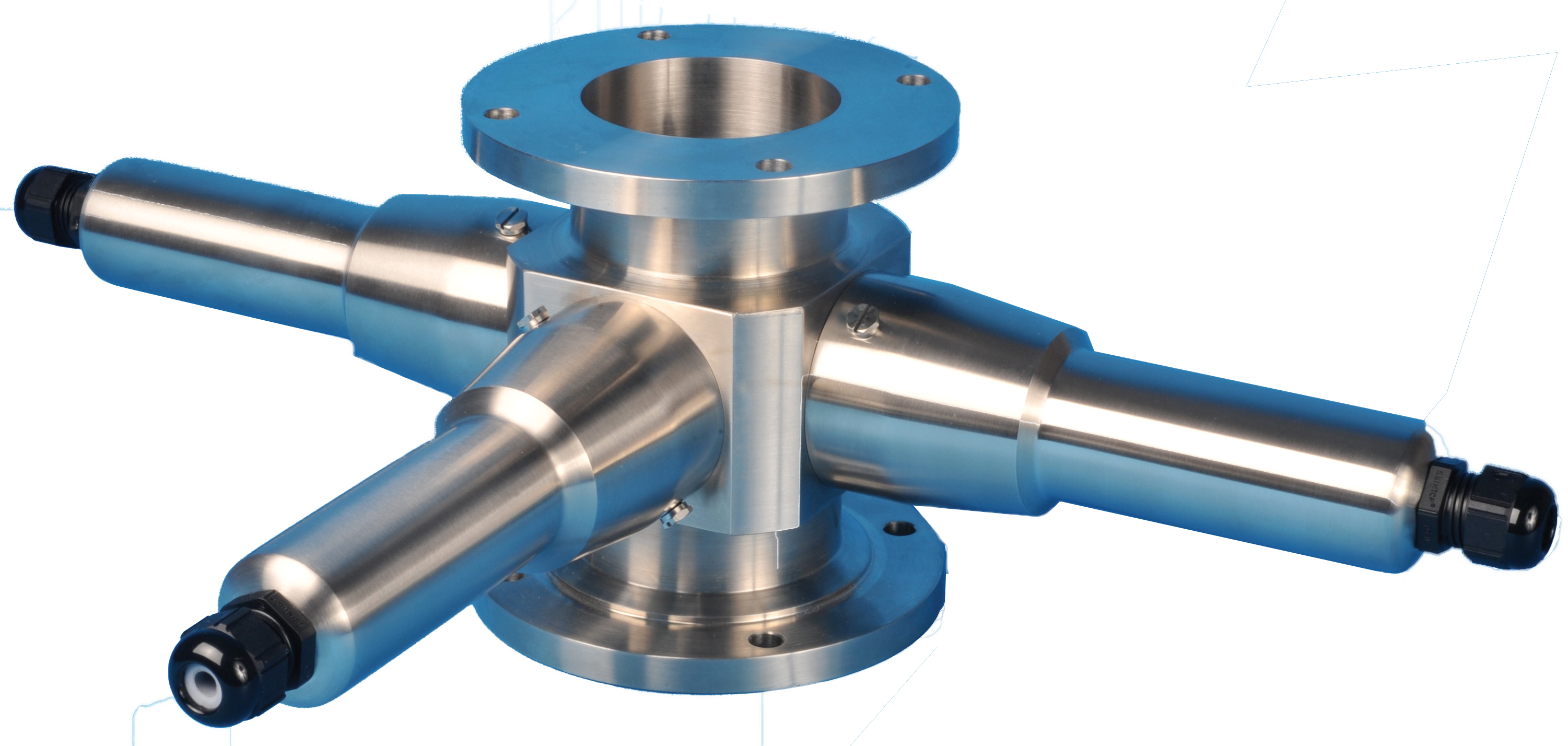

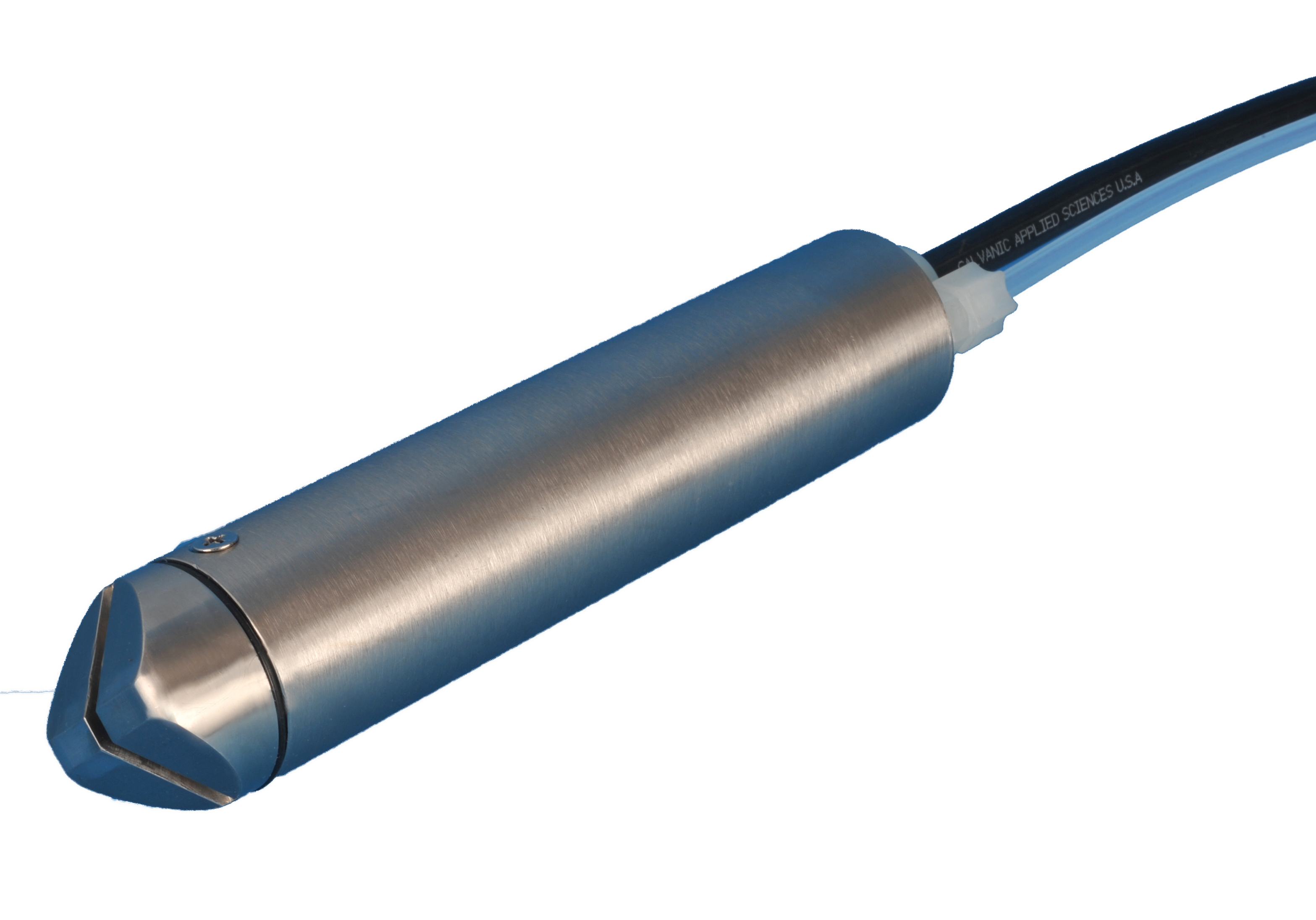

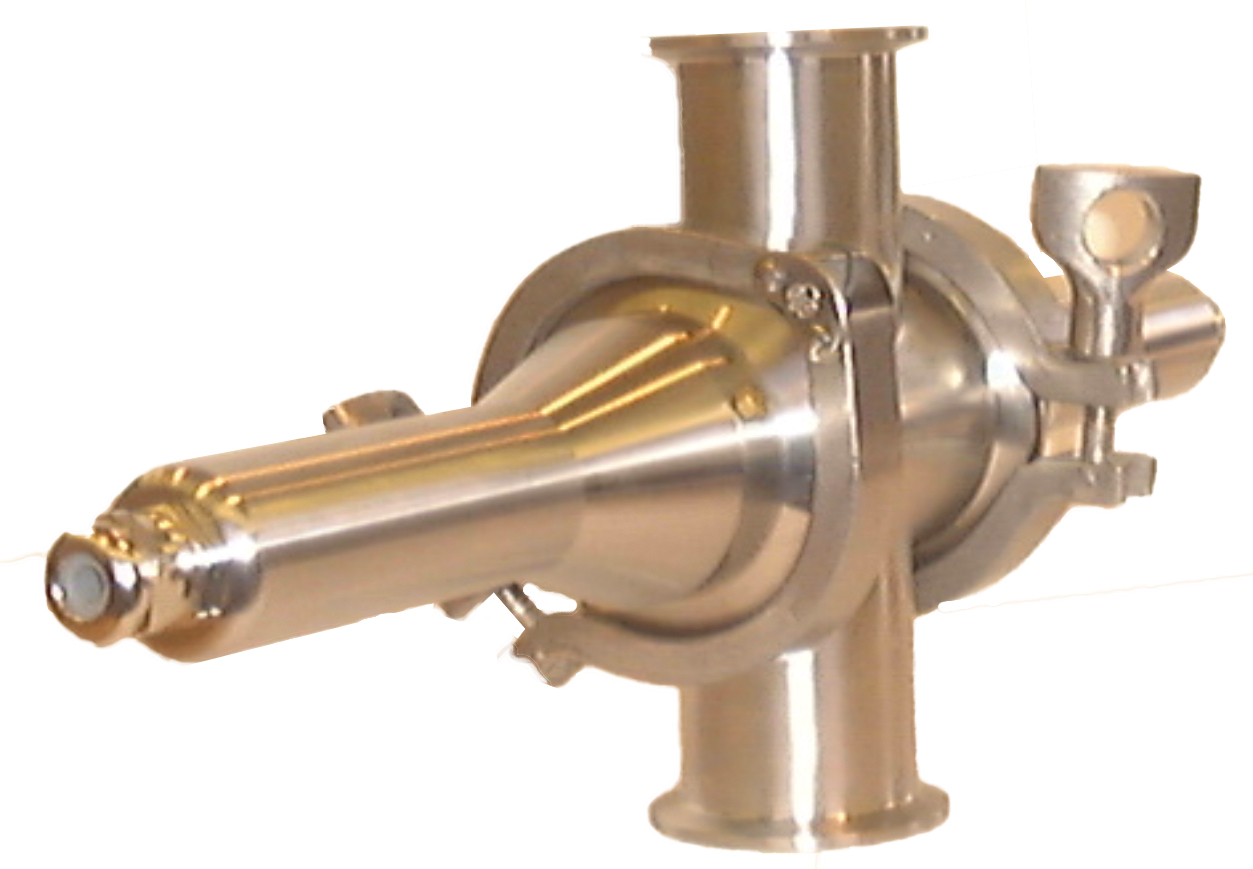

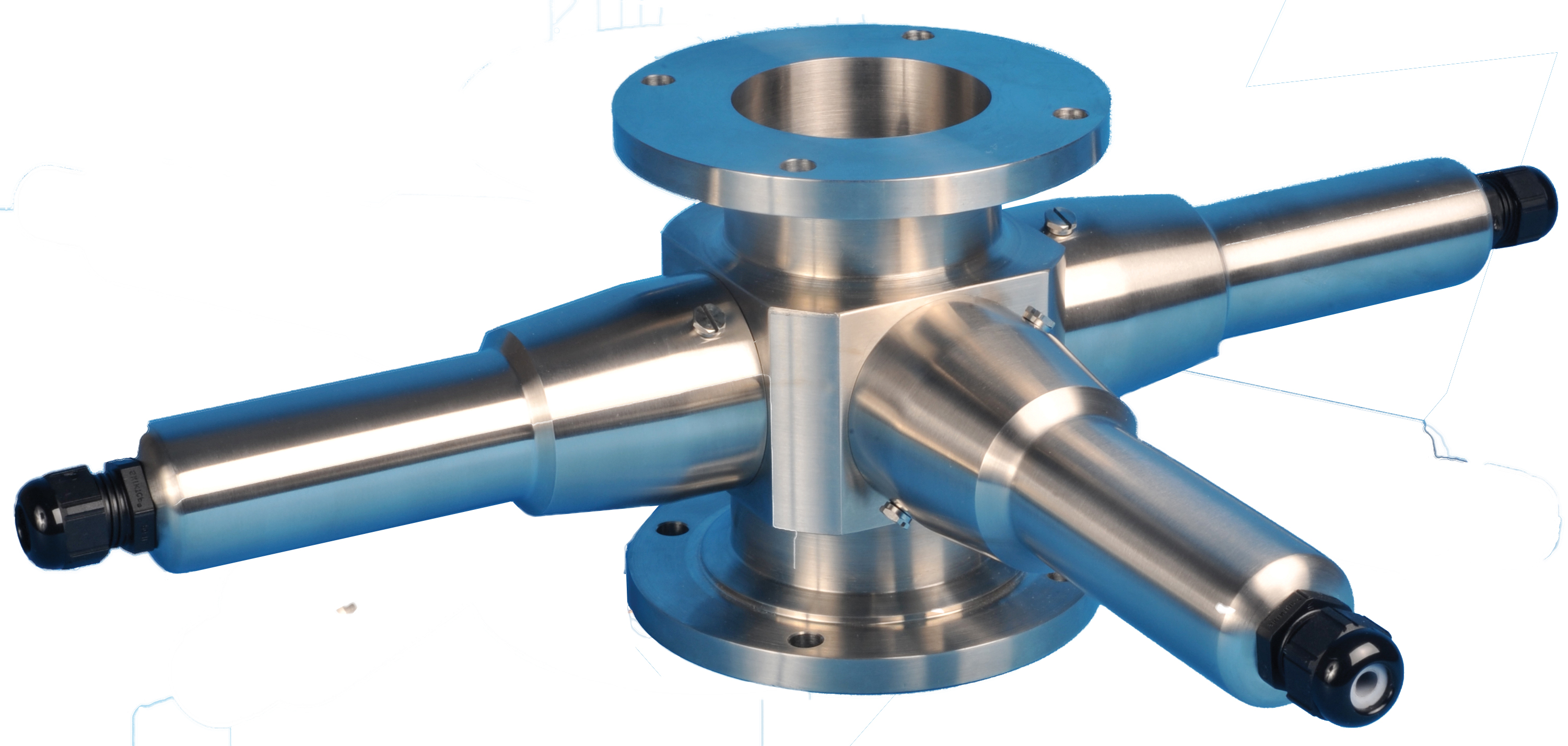

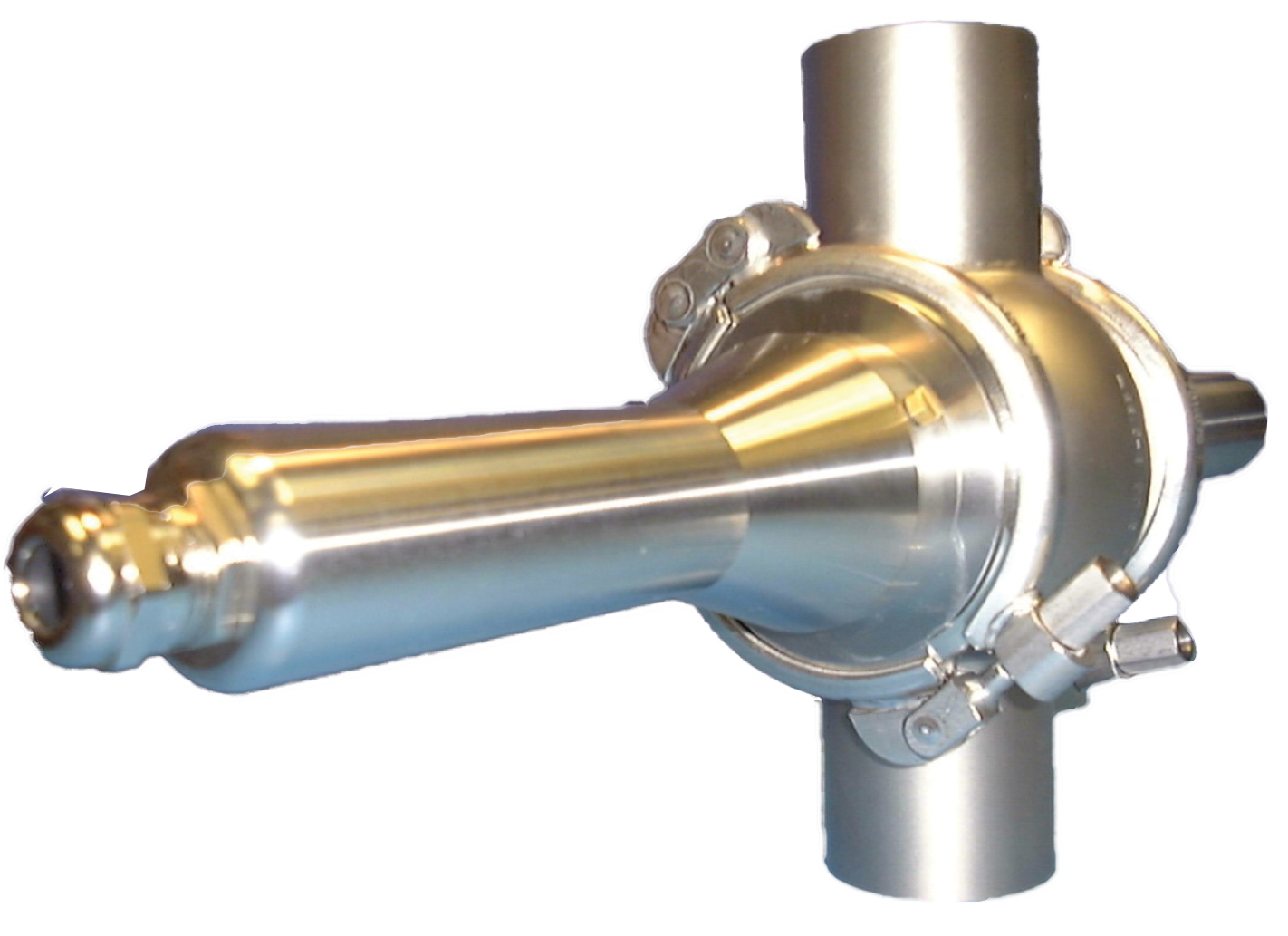

Monitek’s two-component systems include modular, fit-for-purpose in-line sensors and submersible, insertion, and cell-density probes. These sensors pair with a messenger controller, which features intuitive multi-language graphical interface, setup via laptop PC or touchscreen, depending on model, automated cleaning cycles, and more. Unlike most turbidity, concentration, and color monitors, which can handle only one probe at a time, Monitek’s universal messenger controller can handle up to four discrete inputs, each individually controllable to monitor different streams or parameters, dramatically lowering the overall cost and complexity of system set up and operation.